Vacuum pumps are integral to a wide variety of manufacturing processes, from food packaging to drying electronic components, bottle filling machines to biogas production.

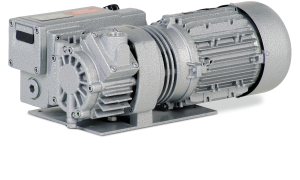

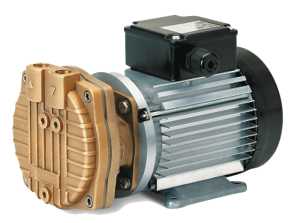

As authorised distributors of Elmo Rietschle, we offer vacuum solutions for your applications. Whether your system requires dry-running or oil-lubricated, low noise output or small footprint, we can support your needs and your industry.

Direct Air offers a range of vacuum technologies including claw, liquid ring, rotary vane (oil lubricated and dry running) and screw.

These products are suitable for many different applications and industries, including the following:

| Central Vacuum | Pneumatic Conveying | Packaging | Pharmaceutical |

| Plastics | Printing & Paper | Chemical | Glass |

| Food & Beverage | Medical | Industrial Parts Cleaning | Automotive |

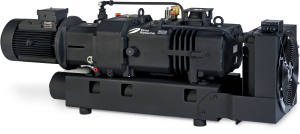

Vacuum Pump and Blowers Service and Repairs

As well as supplying new vacuum pumps, we provide on-site servicing and ongoing maintenance for vacuum pumps to keep your system running and performing efficiently. We recommend implementing a regular service schedule and vacuum health checks to reduce risk of breakdown.

We provide genuine aftermarket parts and supplies on all pump and blowers product to enable repairs and minimise downtime.

We support all of the main manufacturers including Elmo Rietschle, Busch, Becker and Edwards.