The capital cost of buying a compressor is actually only a small part of the overall equation, and we want to ensure our customers obtain the lowest possible cost of ownership.

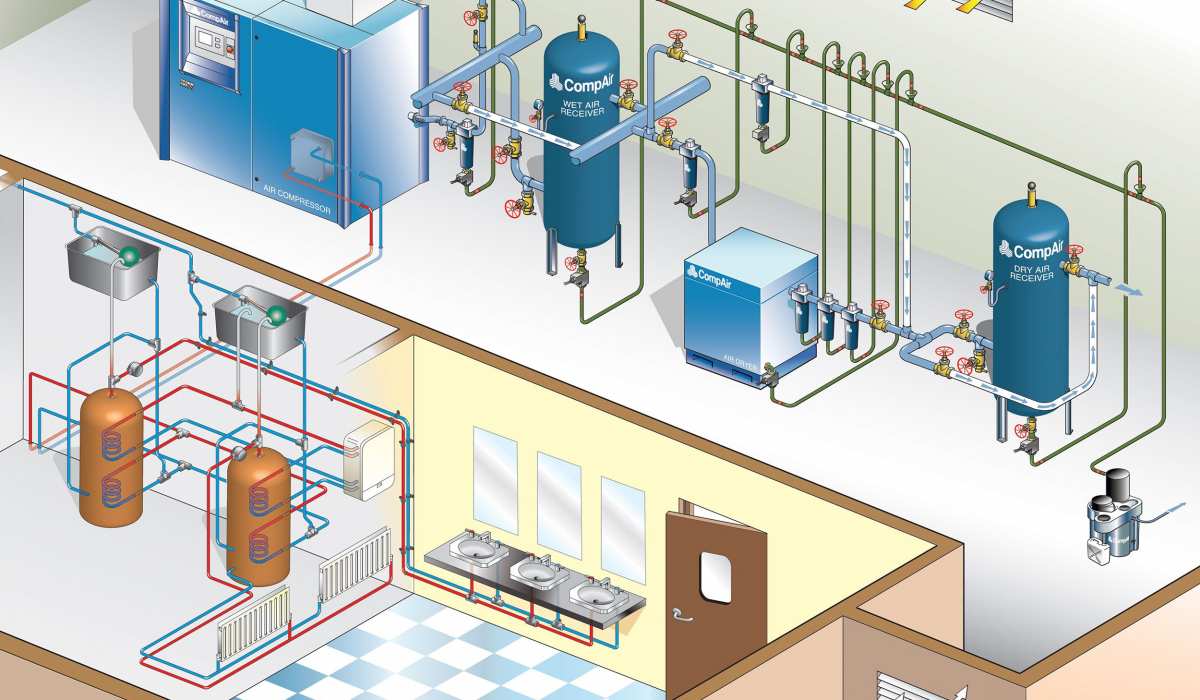

A system design specific for your requirements is key to reducing costs, managing your system’s energy efficiency for ISO 50001 and ensuring environmental responsibility for ISO 14001.

‘If you cannot measure it, you cannot improve it’

Undergoing an energy audit is often the first step to improving the energy efficiency of your compressed air system. We survey all areas of the system in order to minimise energy consumption throughout, including generation, treatment, distribution and process usage.

Direct Air promise to guarantee projected savings from any survey conducted so you can restore control of your energy management and reduce your businesses carbon footprint.

Read more

Compressed air is one of the most important utilities for industry, which makes it also one of the largest consumers of energy. Therefore, compressor energy savings have significant impact on overall business costs and on the environment.

The capital cost of buying a compressor is actually only a small part of the overall equation, and we want to ensure our customers obtain the lowest possible cost of ownership. The right system design is key for reducing costs, managing energy efficiency and environmental responsibility.

If you cannot measure it, you cannot improve it, which is why we survey all areas of the system to improve efficiency. We guarantee projected savings from any survey, so you can reduce your carbon footprint and restore control of energy management.

We use data logging equipment to compile a detailed survey of your system’s condition and efficiency, including flow, energy, operating temperature and dew point. We typically install data loggers for a week to monitor your system and pick up issues like leaks, poorly designed pipework and unnecessary bends or fittings – which we can modify to improve performance. We have ultrasonic leak detectors to measure and pinpoint the location of an issue and flag it for maintenance, as well letting you know the repair costs. We can also redirect the heat generated by your compressed air system to put it work in other areas of your business, which can save thousands of pounds every year. Based on these findings we can provide a range of solutions to improve efficiency and save costs.

Any questions? Get in touch

ENERGY AUDIT

We offer compressed air usage audits in accordance with ISO 11011. Using data logging equipment, we compile a detailed survey of your compressed air systems with particular reference to energy and the operating efficiency. We can monitor pressure, flow, energy, operating temperature and dew point, as well as carbon reduction.

LEAK DETECTION

Did you know up to 40% of your generated compressed air is being lost due to leaks? Air leakage is the single largest waste of compressed air. Direct Air offer a compressed air leak detection service to locate leaks, estimate leakage costs, calculate repair costs and provide a detailed report for corrective actions.

HEAT RECOVERY

Approximately 10% of all electricity used in industry is accounted for by compressed air systems. Did you know over 90% of the electrical input to a compressor is lost as heat? Installing a heat recovery system is simple to do. It works on any make of compressor and can be achieved at initial installation or as a retrofit.

Variable Speed Air Compressors

Variable speed compressors are designed to save energy. The technology enables the compressor to automatically adjust its motor speed to match the air demand.

FLOW MONITORING

Direct Air offer compressed air flow meters to help identify potential savings, overloads and weak points in your system to improve its efficiency. By measuring the actual flow to the various production units, you are in a position to make decisions based on facts.

At Direct Air, we provide a guaranteed ROI that predicted savings from a compressed air installation will be met following the implementation of the system.

Enquire today

Complete the form below to contact the Direct Air team with your enquiry.

Talking to us is easy

We're happy to explain how all our products work and to help you get started over the phone. Real people, plain English and no obligation.

Services

We offer complete compressed air solutions including design, installation, servicing & WSE inspections.

Products

We consider your entire compressed air system from the compressor to downstream equipment & pipework.

Industry / Sector

Whatever the industry and whatever the application, there's a growing demand for higher-quality compressed air.