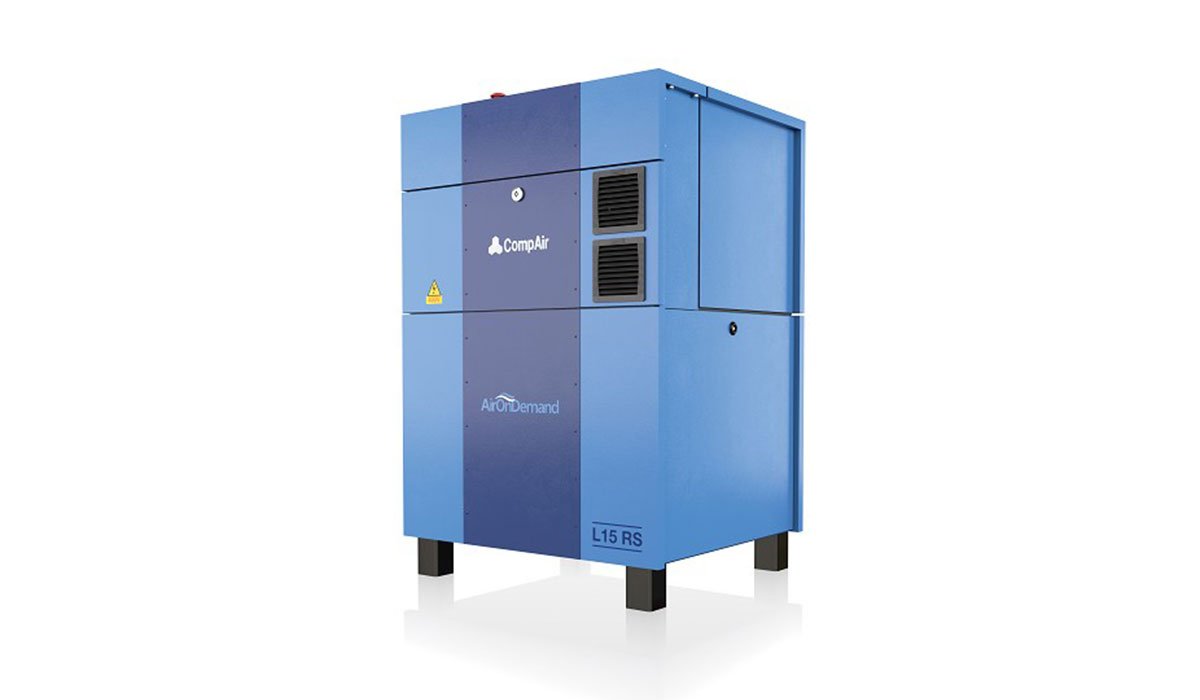

Oil-lubricated compressors are reliable and efficient machines that can be used in several industries to power a wide range of tools and applications. Although these compressors are oil lubricated, they can be connected to downstream equipment including oil filters and dryers to remove oil from the air before it reaches the application.

Most air compressors use oil to lubricate parts within them including the cylinders to protect the pump. These parts work alongside an intercooler keeping temperatures low and preventing overheating. There are different types of oil-lubricated technology available including lobe, screw, vane, liquid ring, and scroll. These compressors also come in various sizes and capacities.

How do I choose between oil-free or oil-lubricated?

The first step in understanding which compressor technology type to purchase for your system is to assess the requirements of the facility and applications which need powering. When the risk of oil contamination is too high and air purity is essential, many businesses will select an oil-free compressor to assist with compliance. This is common in industries like Food & Beverage, Medical & Healthcare, Pharmaceutical and even Automotive where breathing air applications are required. These industries would be using compressed air for food processing, sterilising surgical equipment, product drying and many more.

However, many industrial processes still use oil-lubricated compressors, as the compressed air doesn’t come into direct contact with the end product and therefore, poses no danger to the consumer. This includes industries like Distribution, Engineering and some Manufacturing companies. The applications being powered by oil-lubricated compressors here would consist of conveyor belts, picking machines, metal cutting and many more.

Still unsure of the compressor type that you need? Don’t make the decision alone!

To ensure that you’re selecting the correct option for your system, our Direct Air team are happy to provide their expertise in providing you with the perfect solution.

West Midlands: See our air compressor services in Birmingham, Coventry & West Midlands

South West: See our air compressor services in Bristol, Gloucester, Cheltenham & the South West